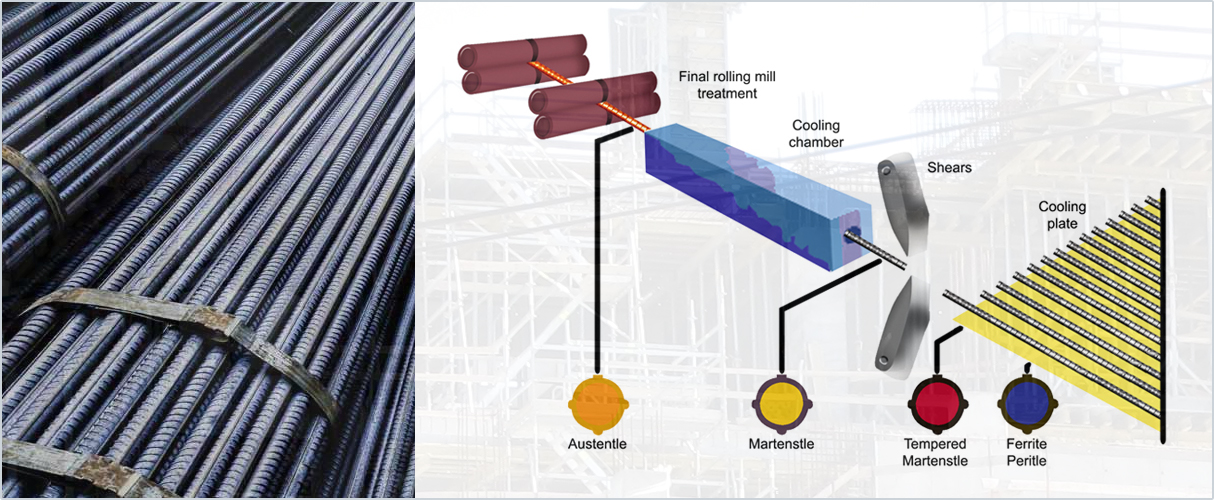

THANE TMT (THERMO MECHANICALLY TREATED) BAR IS ROLLED OUT OF THE WORLDS PROVEN GERMAN CONCEPT. THE PROCESS INVOLOVES THREE STAGES I.E.

QUENCHING : Reheated billet goes through rolling process and is passed through the quenching process, where the surface of the bar is cooled to martensite, while the core is still austenitic.

SELF-TEMPERING : Heat from the core of the bar dissipates to the surface allowing to form tempered martensile, while the core remains austenistic, this process is called self tempering.

ATOMOSPHERIC COOLING : Where in the bar is cooled on the cooling bed, results in the ausstenitic core being converted into ductile ferrite-pearlite core. Thus making THANE TMT blend of strength and ductility.

Implemented in more then

PROJECTS

Office no. 14,

Steel Yard House, 2nd Floor,

Sant Tukaram Road,

Iron Market, Carnac Bunder,

Mumbai - 400 009